Flight Design

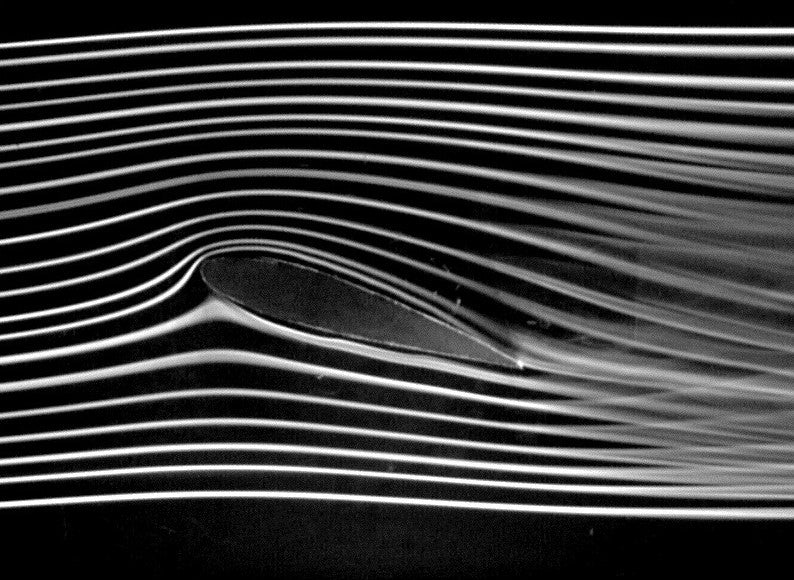

As Omen’s first foil, we wanted the Operator to exceed expectations in the widest range of applications. Extensive testing, iterative design, and feedback from all levels of rider increased our understanding of the interaction between various aspects of the design, and how they create the sensations felt while riding. This open mindset enabled us to optimize performance while mitigating compromises.

Stall speed and angle, minimum power requirement, cruising speed, and top speed stability were focal points of the airfoil design. Everything from light wind ocean swell on a downwind SUP to well overhead waves are well within the Operator’s comfort zone. Choosing what foil to ride is easier than ever.

Turning Performance

Another central design goal was to maximize glide without compromising roll response. Pushing the wingspan out to 90cm for efficiency, it was clear that a unique design would be required to keep turning feeling natural. Through many iterations, the variables contributing to roll response have been teased out and incorporated into the profile of the Operator. The 1050 strikes a natural feeling balance between unreactive and over-tuned.

The next problem with the higher aspect design was wingtip breaches in hard carves or sailing upwind through waves. Investigation of this phenomena led to the discovery that the combination of upturned wingtips and certain airfoil pressure distributions mitigate unpredictable loss of control during breaching. Adjusting these factors led to the ventilation resistance and minimal control change characteristic of the final variation of the Operator design. This is a wing you can push to your limit with confidence.

Uncompromised Mast

Omen worked alongside NoLimitz to design an incredibly stiff, efficient, responsive, and light mast. The foil section has been refined to minimize drag across all AoAs while resisting ventilation during aggressive turns and upwind tacks. The subtle rake reduces yaw stability change at different ride-heights, increasing the sweet spot in the water column.

Built at the ICE aerospace facility by skilled technicians, the mast represents a union of precision manufacturing technology, materials engineering, and years of foiling experience.

Streamlined Fuselage

Foils fly at a positive angle of attack at low speed and transition through neutral to a negative angle at high speed. Because of this, the fuselage has a much greater impact on drag than conventionally thought. Since the primary goal of the operator series was to achieve the greatest possible efficiency over the widest possible range, the shape and size of the fuselage is as streamlined and small as possible.

Using 316 stainless steel for the highest load areas and forged carbon fiber for the stiffness critical extension, the Operator maintains an ultra low profile and glides further across an unprecedented range of speeds.

This efficiency combined with the low drag connections and fairings created a positive feedback loop. Since the tail doesn’t need to provide as much stabilizing downforce, more efficient designs can be used. This further reduces the system’s overall drag and stabilization requirement. The end result is greater glide, easier takeoff, and less effort in pumping without sacrificing control at high speed.