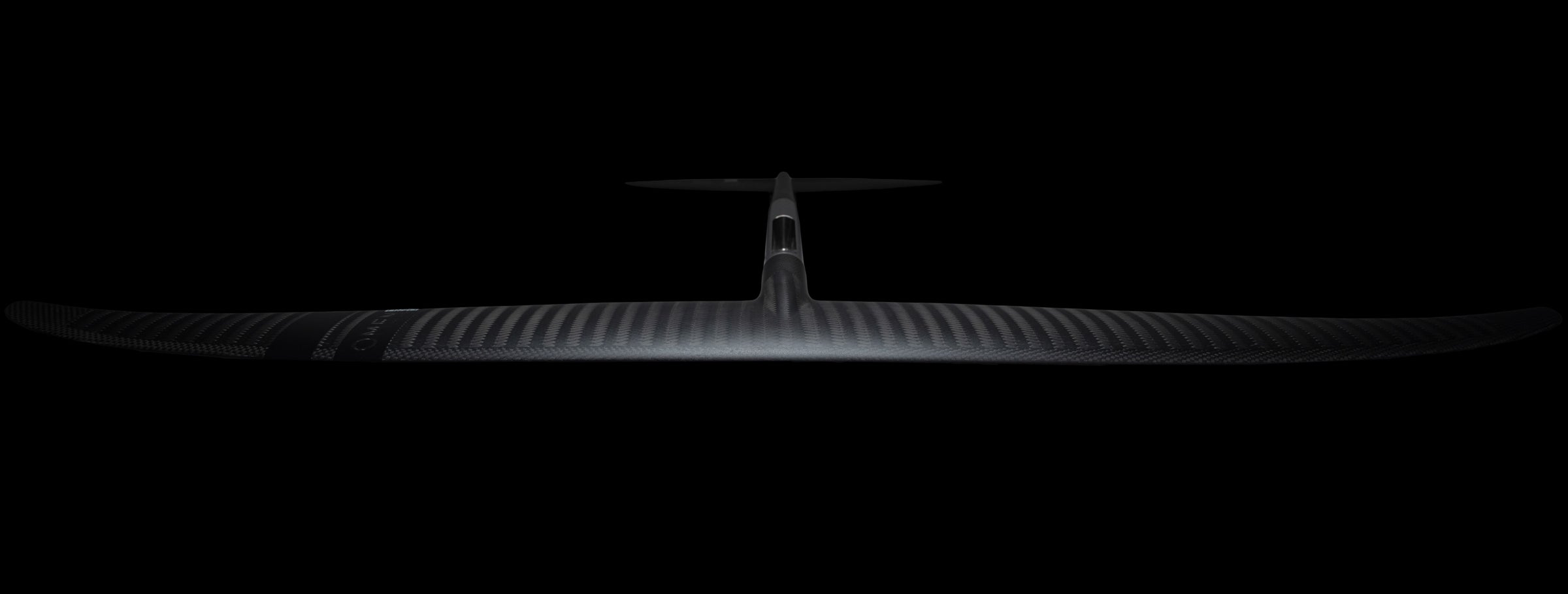

Round Cross Section

The round cross section was designed to reduce both skin friction drag and form drag. Skin friction drag is a function of surface area and a cylindrical shape has the highest ratio of volume to surface area. This allowed us to reach the required strength and stiffness in bending and torsion with the absolute minimum drag induced by skin friction.

The shape also provides the best aerodynamic performance in instances of high or low pitch, and aggressive yaw as the flow remains less disturbed. Although more labor intensive to produce, the performance benefits of a round cross section are well worth the expense to the Omen team.

Precision Construction

The pre-preg carbon SMC material of the fuselage is formed at over 1400 psi for high dimensional accuracy. The scarf joint to the CNC’d 316 stainless steel section creates a high strength, precise, and low drag joint. Ultimately, this makes for a solid connection within the foil and ensures the front and tail wing are perfectly aligned for maximum efficiency and stability.

Lightweight

The light weight of the fuselage extension shifts the center of mass of the foil system further forward. By allowing the foil to be mounted further forward on the board, while keeping the entire system balanced, low end and pumping performance is increased without compromising high speed pitch stability.